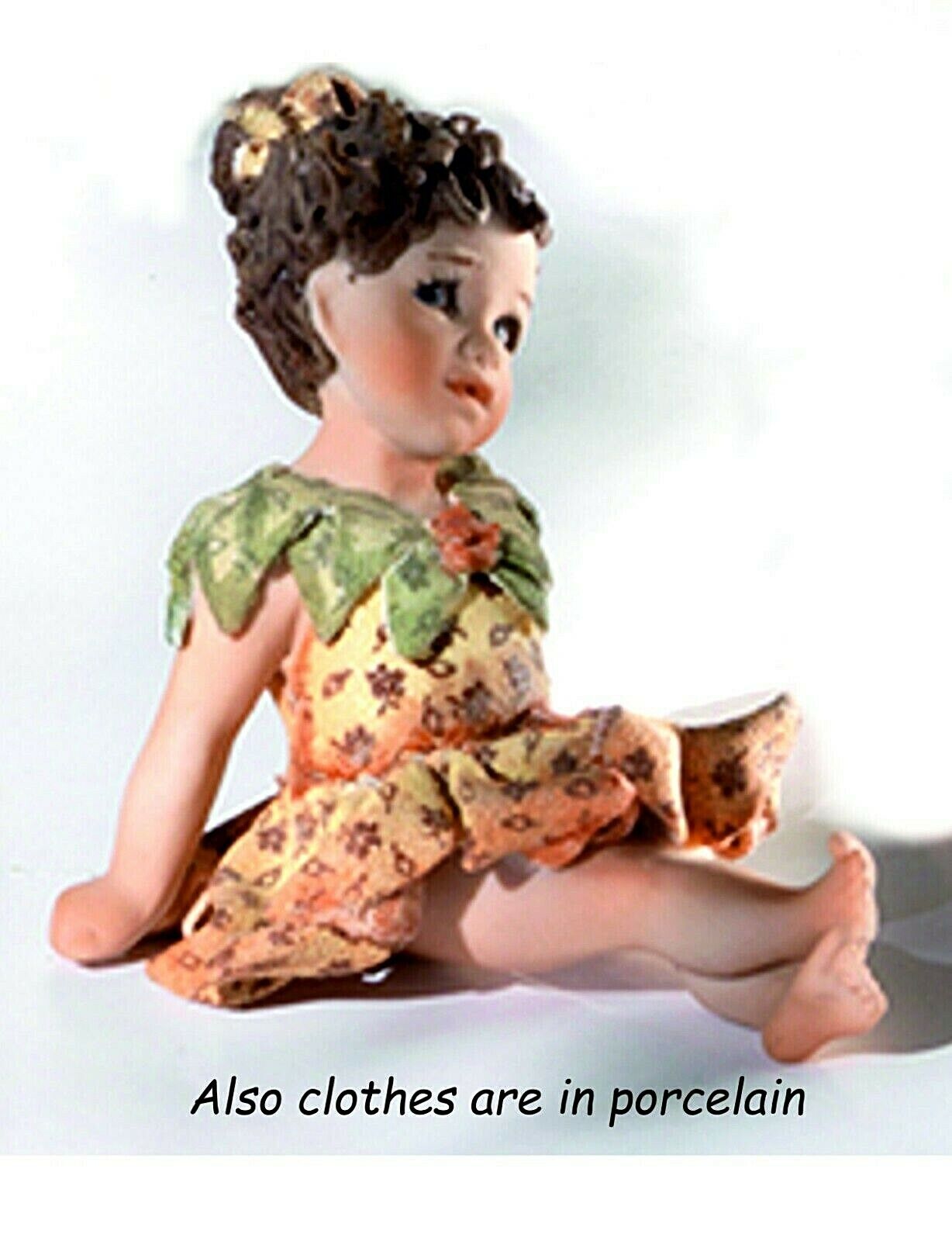

Figurine Porcelain Italian Figurine Of Girl Sitting Sculpture

Contact Us to get a Quote€339.41

The artistic porcelain

Starting with technical concepts and stylistics of the Capodimonte porcelain school, respecting the tradition of the artisan workshop and with a meticulous research on materials for continuous product innovation, these enchanting figurines are born.

The whole creation process takes place in Vicenza, Italy, where expert craftsmen, model makers and painters they take care of the pieces, finishing each statue down to the smallest details and giving each face its own expression.

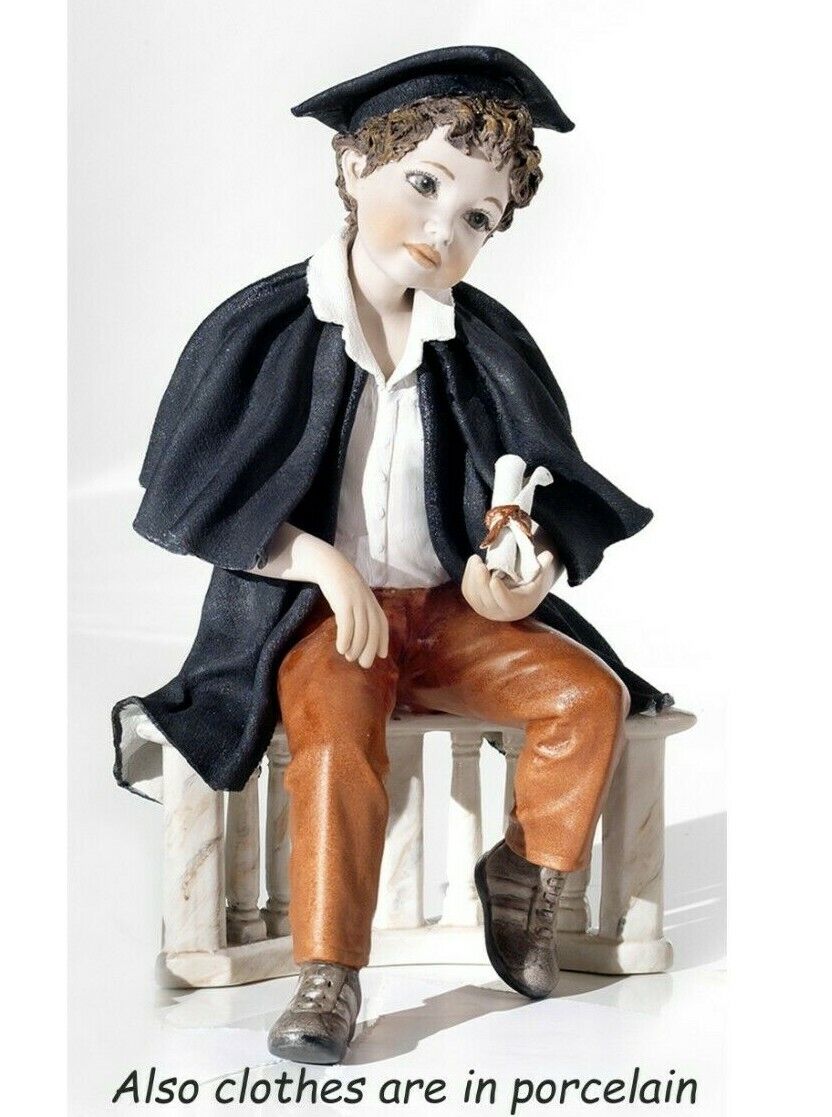

These children’s figurines represent the infantile world with its purity and naivety, a more modern and contemporary representation like their particular expressiveness.

Collectables or gift items, but also favors of particular value:

The emotions they transmit can easily convey a thought, a message for

whoever wants make a precious gift, but it can also be a piece of furniture.

Here are other figurines from our enough collection. . .

Production phases.

SCULPTURE

Starting from a block of clay that is modeled to obtain that face, that expression of the object that you want to represent.

THE MOLDS

The sculpture is sectioned into several parts and a mold is obtained from each.

THE FOGGIATURA

Porcelain is a mixture of kaolin, feldspar, quartz and water. The casting that is poured into the mold.

FINISHING AND ASSEMBLY

Removed from the molds the pieces dthey need to be smudged and refreshed.

The figure is reassembled by assembling the various components.

Finally, all those details are applied that need to be made by hand and which are the value of craftsmanship.

THE LEAFLETS

What we believe to be one of the elements that most characterizes us is grafted here.

By studying the characteristics of the materials we have created thin sheets, created with a special tulle dipped in porcelain. Then we developed a method that allows us to print on these decorative motifs typical of fabrics.

The sheets thus decorated and still in a plastic state are cut according to the desired shape to “dress” the figurines.

These sheets put in the oven are transformed from fabric into porcelain, so it is that our porcelain pieces seem to be made with real fabric.

The hair is thin strands of porcelain that from time to time are combed over the bare head.

These stages of processing are very delicate because every mistake causes cooking defects and extreme care is required in handling the sheets without damaging the decorations.

COOKING

Each piece is dried and further dry finished to remove any defects.

During cooking at 1300° C, the porcelain dough comes close to its melting point.

DECORATION

After cooking over high heat, the bisque is cleaned and sometimes smoothed and decorated.

According to the Capodimonte technique.

Finally there is the cooking of the color, or third fire.

QUALITY CHECK

Finally, any details are added such as the shoulder straps of the bags or the strings of the violins, applied cold on the finished piece.

The pieces are carefully checked one last time.

Each item produced by Sibania is absolutely unique.

Both in the realization of every single piece.

Both in the technique of production that has no equal and that makes it inimitable.

Our ladies of yesterday and today. . . You can find them all in our eBay shop

The article will be made to order.

For this reason Refunds for afterthought are not accepted.

Times maximum production time: 5 to 10 days for some items.

There are many pieces that have passed the first stages of production

If you need delivery earlier than the deadline,

you can contact us for availability or exact timing.

For shipments to Canada, the United States and Russia, the travel time is 7 to 15 business days.

If you need faster delivery, please contact us we will give you a faster service quote.

The products sold are not subject to any import tax or customs duty, if the product is sold and delivered in Italy or within the European Union.

In the case of deliveries to countries outside the European Union, the products may be subject to import taxes and / or customs duties depending on the type of product and the country of destination.

For more information, you can contact eBay customer service or your country’s customs office.

In all cases, any costs related to import taxes and / or customs duties will be borne by the buyer.

Other figurines that you find in our eBay store, come and visit us !!

Additional information

| Finish | MATTE |

|---|---|

| unit type | Figurine |

| Vintage | NO |

| Mounting | Independent |

| Room | Lunch room, Bedroom, Bed room, entrance hall, Study room, Living Room, Foyer, Office |

| Production style | CAPODIMONTE |

| Features | Hand painted |

| Brand | Sibania |

| antique | No |

| Instructions of care and maintenance | Easy maintenance |

| Tailored | No |

| Material | Porcelain |

| Department | Teen, Girl, Boy, Newborn, Adult, Child unisex |

| Country of manufacture | Italy |

| Origin | Italy |

| Theme | Girls, children |

| Subject | Lass |

| handcrafted | Yes |

| Color | Multicolor |

| MPN | Does Not Apply |

| Style | Italian |

| Insertion bundle | No |

| Parts additional necessary | No |

| Type | Does not apply |

| Heights | 21 cm |